Spare parts optimisation for maintenance management

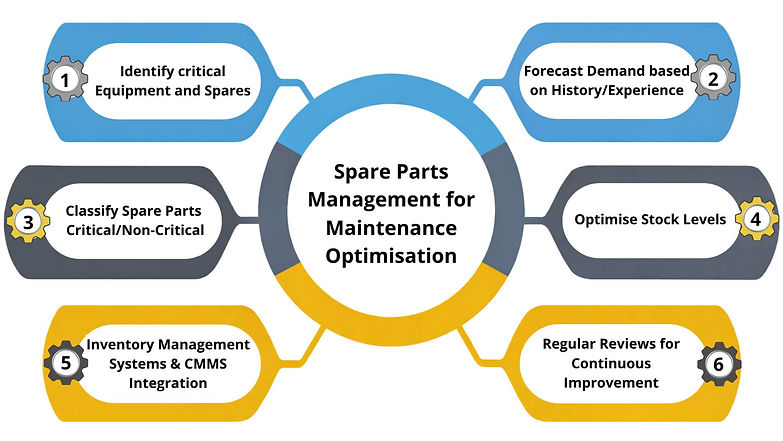

Spare parts management is a strategic process that ensures critical components are identified, sourced, and stored so they are available when needed in the event of a breakdown. It includes collecting and structuring component data, classifying parts by criticality, managing suppliers, and defining optimal stock levels. The key challenge is balancing availability with cost efficiency, using tools such as CMMS and effective store management to ensure parts are in the right place at the right time without overstocking or shortages.

Knowing your equipment keeps costs down

Less Downtime

-

Availability of critical spare parts from internal stores ensure faster repairs and minimal production downtime.

-

Avoidance of last minute, hectic struggles to organise urgently needed parts.

-

Maintenance engineers spend less time searching for parts and can respond to repairs quickly.

Improved Efficiency

-

Timely replacement of parts reduces wear related failures, extending the life of key machinery and equipment.

-

Standardised spare parts records and performance KPIs enable smarter decisions.

-

Continuous improvement based on newly gained experience and data.

Reduced Costs

-

Immaculate parts description and supplier information improves purchasing accuracy and reduces risk of costly errors.

-

Optimised stock levels with less excess inventory, free up capital and lower inventory costs.

-

Data-driven planning enables efficient storage, saving space and administrative time.